Top Four Ways to Improve Ship Maintenance Cycle Times

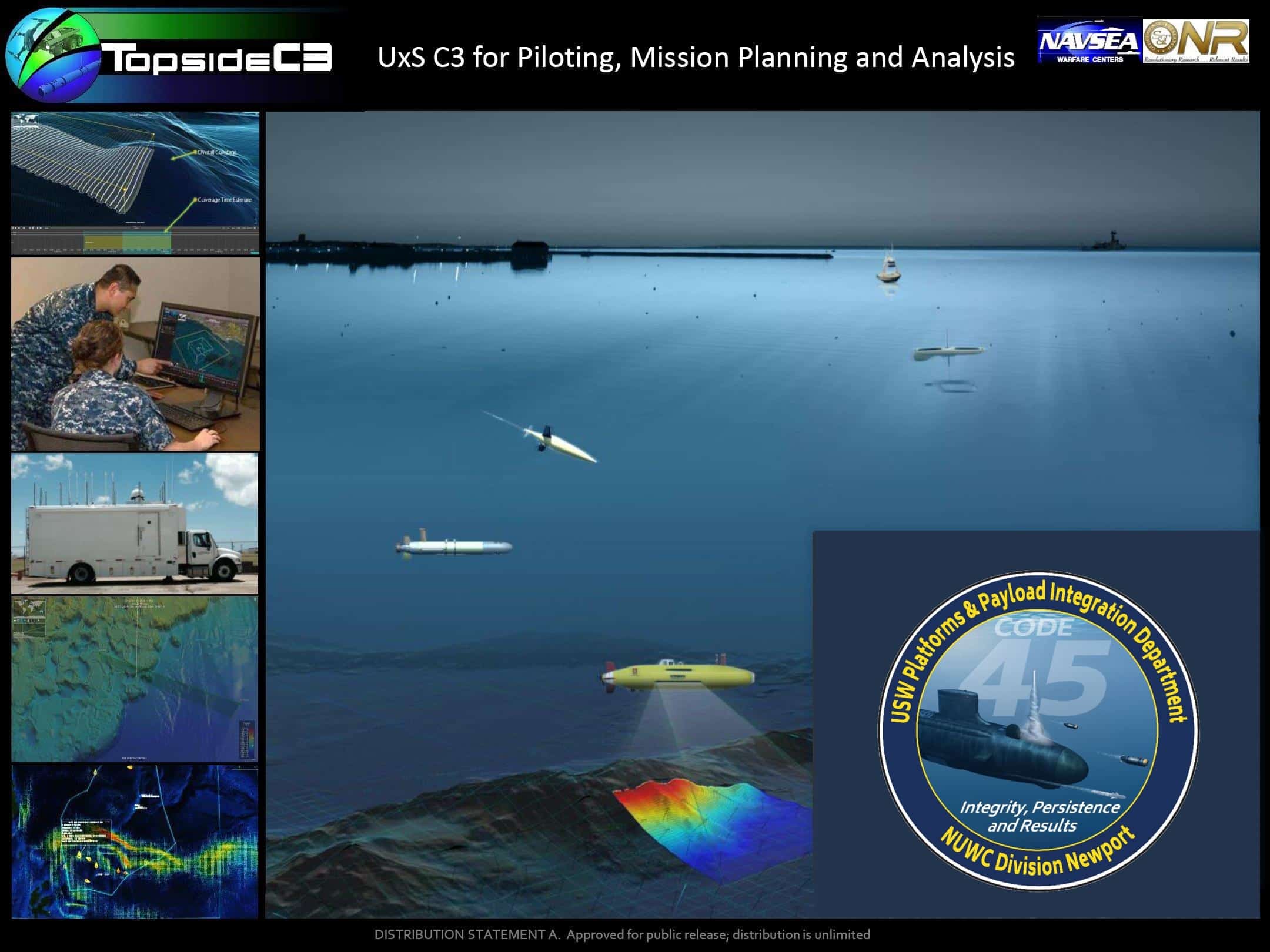

More than ever, fleet readiness is critical to our country’s defense. Maintaining the Navy’s fleet and equipping it with the latest innovations and capabilities is paramount to providing maritime dominance and defending freedom.

Likewise, the sooner subs and surface ships can be serviced, repaired, and upgraded, the better. As a case in point, the Navy set a goal of reaching a submarine operational availability rate of 80% by 2028.

After 25 years of working with the Navy on everything from combat systems to onboard training systems, we have identified four ways to improve maintenance processes and minimize the time ships spend in dry dock.

1). Increase visibility of subprocesses and asset tracking to streamline the entire maintenance workflow

The current maintenance workflow is comprised of numerous specialized subprocesses. While each subprocess may be optimized independently, the overall process usually is not. Intermediate and depot maintenance tasks require coordination with multiple maintenance activities, each with unique responsibilities, tools, processes, and asset-tracking methodologies—all of which can be disconnected from one another.

Mapping the entire workflow process, end-to-end, highlights redundant steps that can be removed. Integrating existing systems provides valuable feedback on whether or not the process is working as planned. A holistic view of the entire maintenance workflow will help detect bottlenecks and breakdowns between processes.

2). Integrate legacy applications and other systems to improve efficiency in real-time

Because maintenance processes, typically performed and tracked manually or with legacy systems, are usually siloed from each other, the overall maintenance cycle time is inefficient and slow. The lack of visibility causes problems when coordinating interdependent tasks, such as:

-

- Legacy tracking systems and apps require significant human touch-time to aggregate data

- Work centers can’t forecast effectively and run out of needed parts

- No real-time visibility of waterfront activities by the depot, which degrades forecasting capabilities

- Supervisors have difficulty putting personnel on tasks

Of course, these and other issues cause maintenance time to expand. Integrating data from existing systems increases the visibility of related tasks and ensures seamless workflow between subprocesses.

3). Centralize data to analyze and further improve processes

As the expression goes, “If you can’t measure it, you can’t improve it.”

With so many different, disconnected processes and systems, measuring the overall maintenance workflow is impossible. Because of poor data visibility and data integrity, maintenance centers miss opportunities to learn what could be done better. Quicker.

Pulling data from existing systems through open APIs allows project managers to continuously improve processes and reduce maintenance cycle times:

-

- Eliminate mistakes in tracking assets by moving away from disconnected systems

- Achieve communication transparency with Program Offices and Fleet Type Commanders

- Gain a clear picture of when ships will be ready to deploy

Process improvement resulting from better communications and visibility across the enterprise enables maintenance staff to provide realistic and reliable repair timelines, ensure that boats are ready for exercises, and prevents operational leaders from having to scramble to find replacement ships and crew.

4). Eliminating administrative work and manual steps allows personnel to do more valuable work

Current manual processes and systems are very labor-intensive, inefficient, and costly. Depot work centers spend countless manhours tracking the location, configuration, and condition of assets. Production Managers spend extra time checking the status of predecessor tasks to coordinate their own tasks. Supervisors monitor manhours locally developed databases and spreadsheets for process choke points and impediments.

Integrating systems and processes provides maintenance staff with the information they need when they need it. This allows personnel to do more valuable work. Maintenance staff can spend more time on repairs and service and return ships and systems to operational commitments. Project managers are freed up to do more analysis and process improvement. By eliminating extra manual and administrative work, maintenance centers can save up to 70% in labor costs.

Integrating disparate applications and systems is fundamental to improving maintenance cycle times and reducing costs. This was the vision behind creating riteMaintenance (TM), our new ServiceNow® application. Centralizing data from systems that support current processes and, if possible, moving processes to a single platform will streamline workflows, dramatically reduce service and repair times, and improve fleet readiness.

Photo credit: U.S. Navy photo by Navy Petty Officer 1st Class Aaron T. Smith. The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.